Overview

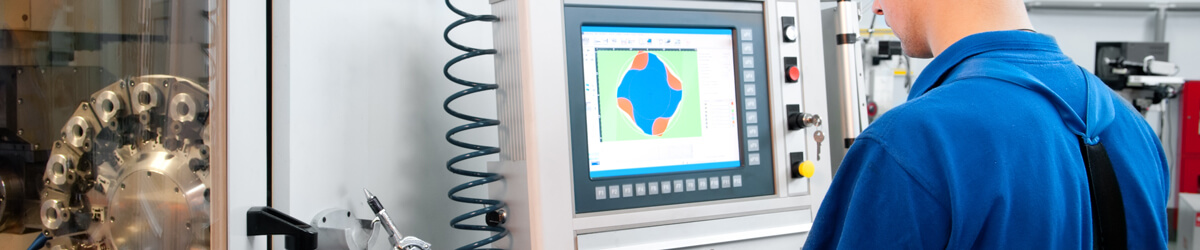

This program can prepare you to work as a CNC operator in facilities using metal and plastic. The first semester starts with 8-week courses that build foundational knowledge. Over the following 8-weeks, you will apply that knowledge and learn hands-on how to operate multi-axis milling and turning machines, making them ready to work as a CNC operator.

The second semester is designed to advance your career with computer-aided design (CAD), computer-aided manufacturing (CAM), coordinated measuring machines (CMM), Lean process improvement, and more. If you are interested in advancing your career even further as a supervisor, manager or business owner, ask us about dual enrollment in the Technical Studies Associate Degree program.

Curriculum Outline

The classes and coursework required is as follows:

Fall Semester

| Course ID | Course | Theory | Lab | Credits |

|---|---|---|---|---|

| MANF120G | Technical Blueprint Reading | 1 | 2 | 2 |

| MANF135G | Technical Math for Manufacturing | 3 | 0 | 3 |

| MANF255G | CNC Milling and Set-up Operator | 4 | 4 | 6 |

| Total Credits | 11 | |||

Spring Semester

| Course ID | Course | Theory | Lab | Credits |

|---|---|---|---|---|

| MANF254G | Quality Inspection and CMM Operator | 2 | 2 | 3 |

| MANF225G | Solid Modeling (CAD/CAM) | 2 | 2 | 3 |

| MANF230G | Manufacturing Ethics | 1 | 0 | 1 |

| MANF112G | Topics in Manufacturing | 2 | 2 | 3 |

| Total Credits | 10 | |||

Total Certificate Credits: 21

Program Specific Requirements

Admission Requirements

- Complete an application for the program.

- Provide proof of high school completion or equivalent.

- Provide an official copy of prior college transcripts, if appropriate.

Health and Safety Considerations

This program includes work in a manufacturing lab where potentially hazardous materials are used. Students will be taught industry standards for safety and will be expected to follow all safety procedures for material handling. Personal protective equipment must be worn. Students will provide their own safety boots or shoes.

Technical Standards

This program includes work in a manufacturing lab and requires participants to physically perform functions that require the following:

- Normal vision for reading instructions and for performing tasks, including inspecting parts for quality (corrective vision is acceptable).

- Mobility and strength for performing tasks that require reaching, walking, standing, and safely lifting up to 20lbs.

- Ability to hear sounds of equipment, for equipment operation and safety.

Transfer Credit Policy

- Students with certificates in technical fields (in areas in which Great Bay does not offer a degree) may complete the Associate’s Degree in Technical Studies.

- Students enrolled in the CNC Certificates program may elect to enroll in the Associate Degree in Technical Studies. Dual enrollment is contingent upon current matriculation or completion of the certificate. Completing the CNC Certificate satisfies the 21 credits required for the technical specialty core of the Technical Studies degree.

Program Outcomes

After completing this certificate students will be able to:

• Demonstrate skills and knowledge required for jobs as CNC machine operators/programmers.

• Demonstrate ability to inspect, test, or measure materials, products, or work for conformance to specifications.

• Apply critical thinking skills to use logic and reason to identify the strengths and weaknesses of alternative approaches to problems.

• Safely operate a 3-axis milling machine, set up and maintain probes and cutting tools, perform basic machine maintenance, and apply tolerance specifications.

• Monitor operation/performance to make sure a machine is working properly, make improvements or take corrective action.