Manufacturing & Technical Skills Training

With over 45 years of experience offering in-demand skills instruction and over 10 years in manufacturing and industrial training, GBCC is a leader in providing relevant, high-skill training required by both individuals and employers. Employers can be assured that employees will gain necessary skills without an interruption to responsibilities, workflow or productivity.

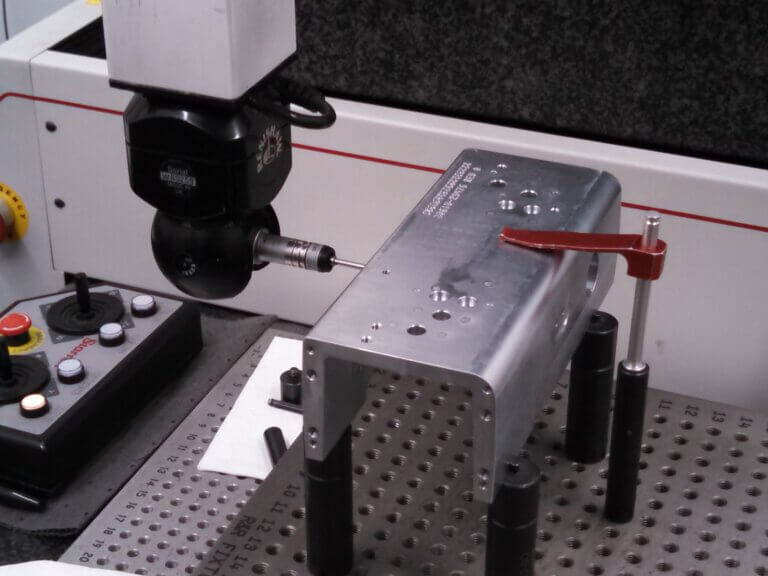

Take one or all four foundational manufacturing skill courses offered year-round at our state-of-the art facility, simulated workspace in Rochester, NH. Each course is 20 hours in length (2.5 hours/day, 2 days/week, 4 weeks).

- Elevate productivity and efficiency

- Fill employee skills gap

- Minimize new employee onboarding

- Minimize current employee training time (off production site)

- Improve employee safety and meet compliance

- Let our industry experienced instructors do the training for you

Courses offer training in:

This course is designed to prepare students for jobs in advanced manufacturing. Topics include an introduction to safety, workplace skills, Lean manufacturing concepts, quality, understanding metals and other materials, heat treating and grinding, hand tool use, precision machining technology, careers in machining and related careers.

This hands-on course prepares students for jobs where they will successfully operate a milling machine with a FANUC and Siemens controller, under the direction of the CNC supervisor. Focus is on developing the fundamental skills needed to use computer numerical control (CNC) to run a milling machine efficiently and within required quality standards. Students will be introduced to Solidworks and Mastercam, will learn the basics of writing CNC code, and will set up and run CNC milling machines. They will maintain cutting tools dedicated to manufacturing and perform machine maintenance.

This course will cover mathematic concepts frequently used in manufacturing and construction, including some review of fractions, decimals, algebra, ratios, plane and solid geometry and applications, Cartesian coordinate system, and right triangle trigonometry with applications including vectors, mean, median and mode.

Students will learn to read blueprints and develop an understanding of how blueprints provide information necessary to control the manufacturing operation and quality outputs. Topics include terminology, standard abbreviations, the different types of lines on a blueprint, and reading different views. Major concentration will be towards ISO standards and geometric definitions, including profiles, parallelism, and true position. Focus will be on both paper and electronic formats. Students will be introduced to CAD environment processes throughout the course. The English inch and Metric dimensional examples will be included. The content is based on ASME Y14.5-2018, Dimensioning and Tolerancing.

Supply Chain Management Courses

In today’s complex world of supply chain management, there are varying degrees of skills and expertise. Managing your supply chain needs is a matter of Planning, Procurement, and Warehousing the materials needs of your organization. Planning what items your organization needs (raw materials to convert or products to sell). After identifying needed materials, the Procurement function is a process of identifying suppliers to provide those materials and purchasing those materials. As those materials are received, they need to be stored to keep the materials safe until they are processed for use. Each of these functions has its own skill requirements and these courses provide entry skills (though, even seasoned professionals can benefit from these courses).

The Supply Chain Procurement Certificate program is a foundational education program designed to help both entry-level and experienced supply chain professionals expand their procurement knowledge and skills. This course will strengthen the participant’s knowledge of procurement and develop and improve skills in sourcing materials and services. The program provides an overview of procurement fundamentals, sourcing strategies, supplier relationship management, negotiations, evaluation metrics, and more.

Synchronization is critical to fast, accurate production and delivery. By engaging all parts of the business, professionals can align planning processes and enable their supply chain organizations to experience significantly fewer disruptions. ASCM’s s Supply Chain Planning Certificate program introduces these essential planning fundamentals and clearly explains how to integrate all planning functions within a company.

Warehouse function has grown and so have the skills requirements for anyone interested in inventory management. The ideal audience are those seeking entrance into materials management or who want to improve their skills to keep up with the fast-changing warehouse functions.

The Supply Chain Warehousing Certificate, developed by ASCM in partnership with Prologis (a leading warehouse provider), signifies the completion of a foundational education program designed to help individuals build their knowledge in warehousing and distribution.

This course introduces global supply chains and the movement of products and materials across businesses, geographies and distribution centers and explains the workings of a warehouse and a distribution center.

The program provides an overview of distribution inventory management, product storage, packaging and shipment, sustainability in logistics and so much more.

Current Course Schedule

A PDF of the current course schedule is available below:

To Register for a Course

Fill out the Rochester registration form.

We will contact you to arrange for payment. Or, you can stop by our Rochester campus (Monday to Thursday 9:30am to 5:00pm or call 603-427-7773) to register in person.

Questions?

Email [email protected] or call (603)–427-7773.